SUBMAR, leading the Way in Hydrodemolition and Precision Abrasive Waterjet Cutting in the Offshore Decommissioning.

Offshore Expertise

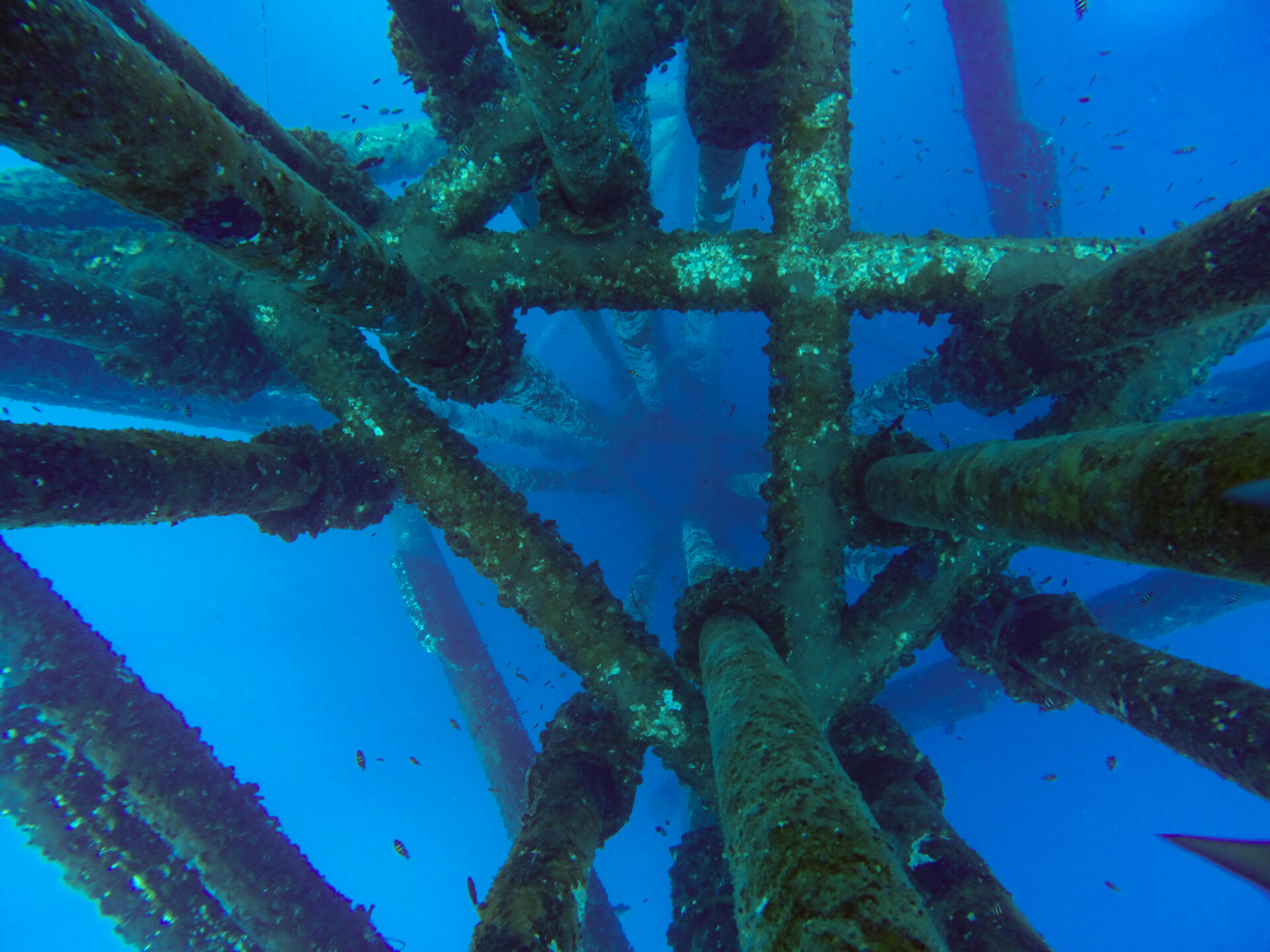

We are experts in waterjet cutting specifically for offshore applications. Our deep understanding of maritime and offshore industries enables us to deliver reliable and effective solutions, especially for the decommissioning of oil rigs.

Advanced Waterjet Technology

Submar uses state-of-the-art waterjet cutting technology capable of handling thick metal structures. Our technology ensures high precision and reliability, even in the toughest offshore environments.

Safety and Efficiency

Our waterjet solutions are designed to operate safely and efficiently in hazardous and confined underwater conditions. We minimize risks and ensure the highest standards of safety, while maximizing operational effectiveness during demolition tasks.

Tailored Solutions

We offer customized solutions, specifically adapted to the unique requirements of each project. Whether it’s cutting through thick metals or working in challenging underwater conditions, Submar provides the flexibility to meet your needs.

SERVICES

Offshore oil and gas platform

decommissioning

SUBMAR delivers offshore decommissioning solutions worldwide, specializing in oil and gas platforms with ultra-high-pressure waterjet cutting up to 4000 bar for precise, efficient dismantling.

Advanced Hydrodemolition for Offshore Decommissioning

The Petroleum Act 1998 mandates removing structures 3 metres below the seabed, and SUBMAR’s hydrodemolition ensures precise, debris-free compliance with strict industry standards.

Abrasive Waterjet Cutting

Submar provides offshore abrasive waterjet cutting services, offering precise and clean cuts on various materials with minimal environmental impact. This technology ensures high-quality, efficient results for challenging projects.

Diving Services

Submar offers professional diving services for subsea inspections, maintenance, and repairs. With skilled teams and advanced technology, they ensure safe and efficient operations in challenging underwater environments.

News

Aberdeen – business trip

SUBMAR Strengthens Its International Position at Subsea Expo in Aberdeen During a recent business visit to Aberdeen, SUBMAR reinforced its...

BOW THRUSTER – successfull replacement

SUBMAR has successfully completed the replacement of a bow thruster, restoring full maneuverability and performance to the vessel....

SUBMAR Renews BV, ABS & AIO Certifications – Strengthening Our Path to ISO

SUBMAR Successfully Renewed BV, ABS and AIO Certifications At SUBMAR, quality, safety, and reliability are at the core of everything we...

Contact

Adress

Leo Baekelandlaan 1,

B – 8400 Zandvoorde (Oostende)

Contact

info@submar.be

+32 50 65 84 30

BTW

BE 0719 519 571

Certified