It’s official – our Multistring Conductor Cutting Head is patented!

And we couldn’t be prouder.

This achievement is the result of more than eight years of research, development, and rigorous testing. The outcome: a cutting head capable of slicing through the most complex multistring conductor configurations in four hours or less – without leaving bridges behind.

The Challenge We Set Ourselves

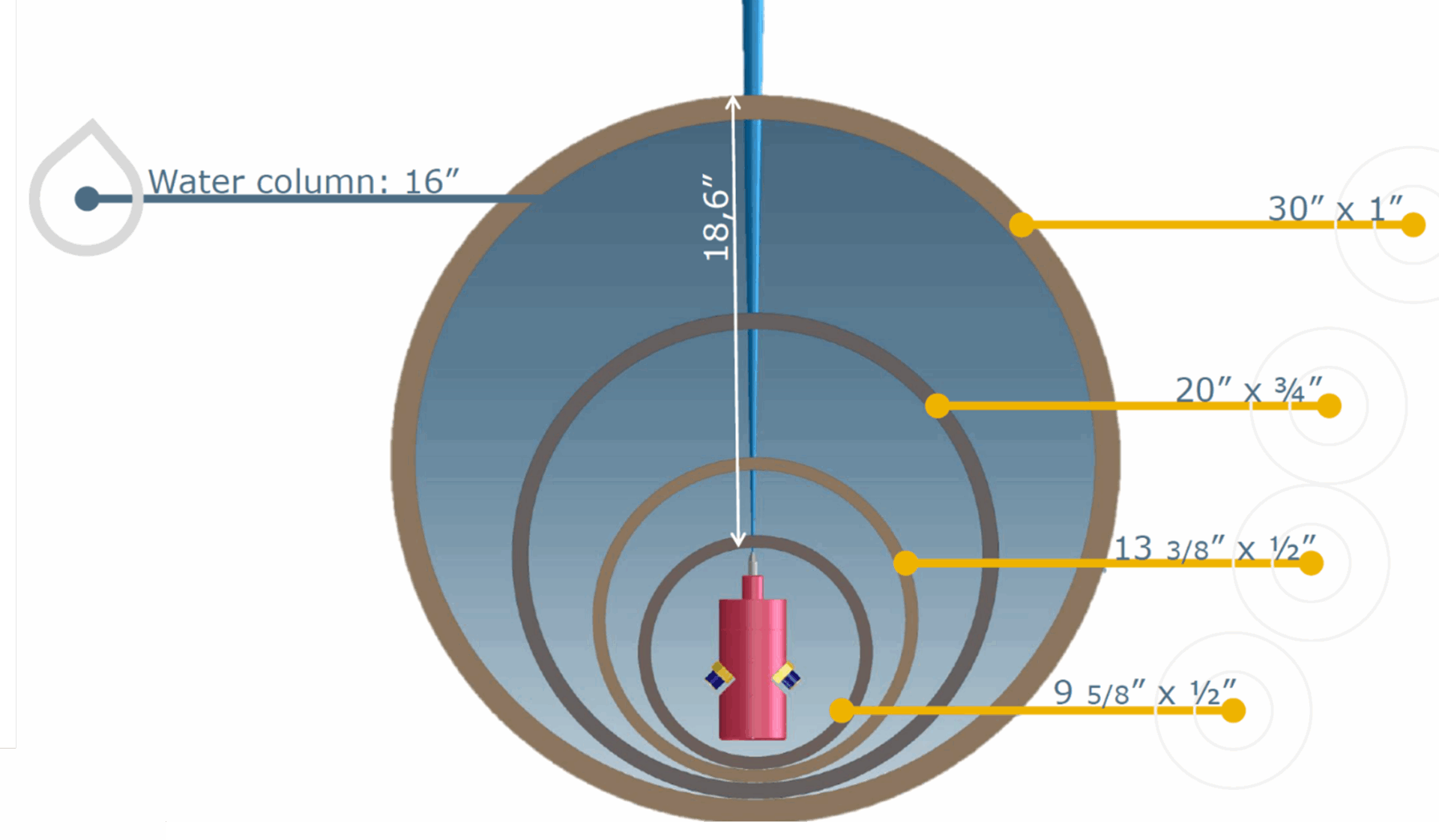

To validate our technology, we tested it against what we defined as a highly challenging multistring conductor configuration:

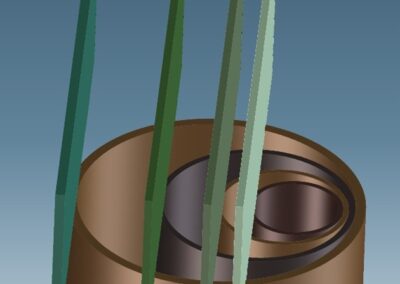

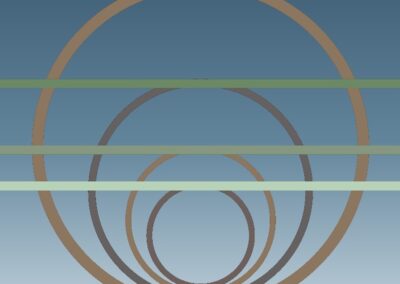

- A four-layer multistring conductor built from standard casings.

- All casings shifted against one another.

- All shifted in the same direction.

- No grout present between the layers.

- All annuli filled with water.

Our conviction was simple: if we could achieve cutting speeds high enough to slice through a 30” multistring conductor at its widest water column point within four hours, then we could cut virtually any multistring configuration within the same timeframe.

And we did it.

The Technology Behind the Success

Our in-house designed and newly patented multistring conductor cutting head consistently achieves the goal:

-

Cuts through even the toughest well structures in four hours or less.

-

Leaves no bridges behind.

-

Delivers reliable, repeatable results.

How We Tested It

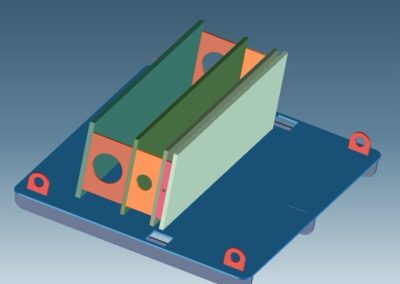

Since straight plates are much easier for measuring cut quality and speed, we unfolded the conductor casings into plates and built a dedicated test station.

-

The plates were held at precise distances with supports and welded onto a base plate equipped with lifting lugs.

-

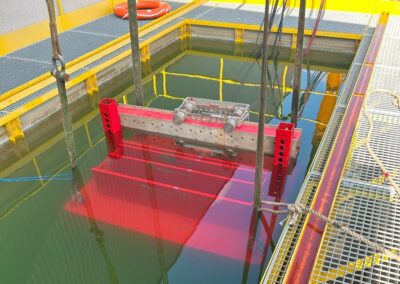

This setup allowed us to carry out repeatable tests inside our large test tank.

-

A cutting beam and carriage system enabled controlled underwater cutting trials.

Over two full days, we tested with multiple parameter sets. Time after time, the results proved that complex multistring conductors can be cut within four hours – even under the toughest conditions.

Results That Speak for Themselves

-

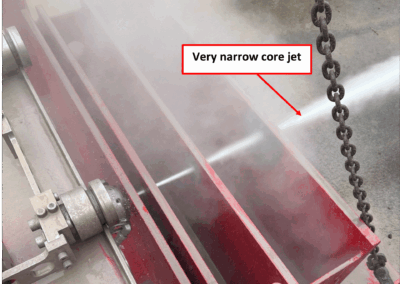

The cutting jet maintained integrity through four layers of material, producing straight, clean cuts.

-

Independent experts observed and confirmed the process and results.

-

Visibility underwater was limited due to abrasives, so much of the documentation was done above water – showing clear evidence of consistent, high-quality cuts.

The key lies in our ability to keep the core jet cohesive, enabling us to cut through complex, layered “sandwich structures” with unmatched precision.

Verified by Experts

In August, we invited an independent panel of eight experts from the decommissioning and abrasive waterjet cutting industries. They spent a full day at our facility, witnessing the process firsthand.

Their verdict? They were impressed – and so were we.

Ready to Take on Your Challenge

With our patented cutting head, we can confidently say: your most complex multistring conductors can be cut in four hours or less.

Want to learn more? We’d be happy to share details and explore how we can collaborate.

👉 Contact us today to discuss your cutting challenges.